knoop and vickers hardness test|knoop hardness test pdf : importing While Vickers hardness testing is versatile and widely used for metallic materials and general-purpose testing, Knoop hardness testing excels in evaluating brittle materials and surface coatings. Glass Only Pyrex® or Type I borosilicate glass is autoclavable. When autoclaving liquids in Pyrex® containers, do not fill more than 2/3 full and do not seal the container.

{plog:ftitle_list}

%PDF-1.5 %µµµµ 1 0 obj >>> endobj 2 0 obj > endobj 3 0 obj >/XObject >/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/Annots[ 19 0 R 20 0 R] /MediaBox[ 0 0 612 .

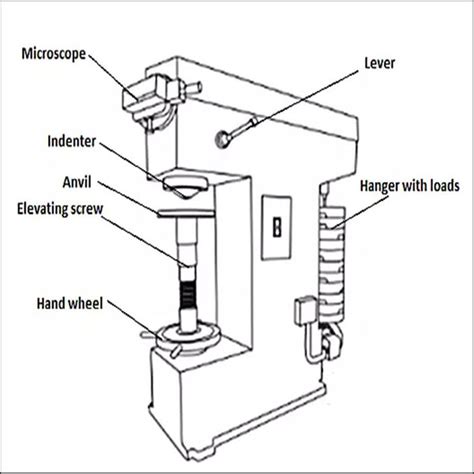

Due the long and narrow (elongated) test indent, the Knoop method is best suited for use with small, longish test specimens, whilst the Vickers method is better for small, rounded specimens (square indentation). While Vickers hardness testing is versatile and widely used for metallic materials and general-purpose testing, Knoop hardness testing excels in evaluating brittle materials and surface coatings. Diagram of a Vickers hardness tester Knoop Hardness Test. The Knoop hardness test is a microhardness test designed for brittle materials like ceramics and glass, as well as for small or thin metal sections. It uses an elongated diamond-shaped indenter to create a shallow, narrow indentation, ideal for measuring hardness on thin layers or . Standard Test Method for Knoop and Vickers Hardness of Materials E0384-11E01 ASTM|E0384-11E01|en-US Standard Test Method for Knoop and Vickers Hardness of Materials Standard E384 Standard Test Method for Knoop and Vickers Hardness of Materials > new BOS Vol. 03.01 Committee E04 $ 129.00 In stock

The Knoop hardness test is conducted in the same manor, and the the same tester as the Vickers hardness test. However, only the long diagonal is measured. However, only the long diagonal is measured. This, of course, .

Rockwell hardness test Brinell hardness Vickers Knoop hardness Shore 3.1. Rockwell Hardness Test. The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in the R, L, M, E and K scales. The higher the number in each of the . Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force units are .The VH3100 Vickers and Knoop hardness test system features a 3-position virtual turret with one Vickers indenter and two measurement objectives, an automated X/Y sample stage (110 mm x 140 mm travel range), a bright field overview camera for sample navigation and scanning and a powerful image analysis. A purpose-designed collision protection .There are two main methods of microhardness testing, both offering repeatable and accurate results: Vickers hardness testing and Knoop hardness testing. Vickers hardness testing. The Vickers hardness test uses a Vickers indenter, which is shaped like a squat pyramid and is typically pressed into the surface of the material for 10 seconds. The .

The general principle of the Vickers and Knoop indentation hardness test consists of two steps: The applicable specified indenter is brought into contact with the test specimen in a direction normal to the surface, and the test force F is applied. The test force is held for a specified dwell time and then removed.Learn more about hardness testing basics here. The Knoop hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an optical measurement system.What are the pros and cons of using Vickers versus Knoop hardness testers for measuring case depth in carburized gears? QUESTION Vickers vs. Knoop Hardness Testers for Measuring Case Depth in Carburized Parts Figure 1 Illustration of the Vickers diamond indenter. 48 GEAR TECHNOLOGY | January/February 2020 [www.geartechnology.com] as the expertthe hardness value is calculated based on the applied load and the indentation size. Vickers belongs to the optical methods. Vickers Hardness The Knoop hardness test is similar to the Vickers test but uses a rhombic-based diamond indenter instead of a pyr-amid. It is commonly used for measuring the hardness of thin

does autoclaving kill bacterial spores

THE VICKERS MICROHARDNESS TEST The Vickers microhardness test uses a calibrated machine to force its indenter, which is a square-based pyramidal diamond with face angles of 136 degrees (± 30 min), into the surface of the material under test; the length of the two diagonal indentations are then measured optically. Vickers hardness number, VHN .Similar to the Vickers test, the Knoop hardness test is used on small and thin parts, using loads of 1 kgf or less. The process is identical to the Brinell hardness test but uses a rhombus-shaped indenter and a microscopic measurement system. 12/13/22, 11:41 PM Hardness: Vickers, Rockwell, Brinell, Mohs, Shore and Knoop - Matmatch .Knoop Metal Hardness Testing is an alternative to the Micro Vickers Hardness testing that was invented by the National Bureau of Standards (commonly known as NIST). Due to the rhombus-based pyramidal diamond indenter paired with micro loads (10gf to 1000gf), the Knoop Metal Hardness Test causes minimal surface deformation on your material.

Buehler's industry leading hardness testing blocks ensure accuracy, integrity, and traceability in hardness testing processes. The comprehensive range of scales and blocks, associated with Rockwell, Brinell, Vickers and Knoop testing.Remove complexity with pre-configured machine setups and effortlessly conduct Vickers and Knoop hardness tests. Wilson ® VH1102 & VH1202 Hardness Testers Versatile and reliable solutions for accurate micro-hardness testing .ASTM E92 is a standardized method in the standard and low force range (200 gf - 120 kgf), used for determination of the Vickers hardness and Knoop hardness of metallic materials, where an indentation is created by means of a diamond .

Similar to Vickers hardness testing, Knoop uses a diamond indenter. However, instead of square indents, Knoop indenters are rhombohedral-shaped, creating an elongated indent, with the longer diagonal seven times the shorter. Unlike Vickers, only the long diagonal is measured, saving time. Knoop indents can be placed closer together .

All information about Knoop hardness testing Test procedure Sample request during the procedure Knoop hardness & methods Discover now. . Evaluation is more precise than the Vickers method, because the Knoop measurement diagonal (longitudinal diagonal) is longer for any given indentation depth. Materials that fall into a very high hardness scale or thin and small components tend to be better suited for Knoop or Vickers testing. Vickers methods are widely used for microhardness testing, which is essential for measuring the hardness of small or thin materials or for analyzing the hardness of specific microstructures in a material.The Wilson VH3300 offers an advanced, fully automated hardness tester for fulfilling both Vickers and Knoop hardness testing requirements. Designed for all users from novice to expert, it utilizes quick and straightforward operation without compromising the flexibility required for advanced applications. The VH3300 is not only a solution for .Hardness, Rockwell Superficial Hardness, Knoop Hard-ness, and Scleroscope Hardness)3 E 384 Test Method for Microindentation Hardness of Ma-terials3 3. Terminology . 3.4 Vickers hardness test—an indentation hardness test using calibrated machines to force a square-based pyramidal diamond indenter having specified face angles, under a prede-

The Knoop hardness test is conducted in the same manor, and the the same tester as the Vickers hardness test. However, only the long diagonal is measured. However, only the long diagonal is measured. This, of course, saves a little time. Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force units are . A revision of the Marshall’s relation is proposed in order to determine the elastic modulus by using only Knoop hardness test instead of both Vickers and Knoop hardness tests. As a secondary conclusion, Knoop hardness test can be a favorable candidate for mechanical characterization of brittle materials where Vickers hardness test is .

vickers hardness test manual

vickers hardness test chart

Vickers and Knoop hardness test methods are defined in the following standards: ASTM E384 and ISO 6507. It is recommended that operators have a current copy of the relevant standards, which are updated regularly. In the Vickers hardness test, a load is applied smoothly, without impact, forcing a diamond indenter into the test piece, as .Micro Vickers and Knoop Hardness Tester – Analogue, Digital and Digital with CCD Optical Analysis Software NG-1000 Series Standards ASTM E384, ASTM E92, ISO 6507 . Standard with (HV & HK) Vickers and Knoop hardness testing capabilities. 8. OK/NG judgement function. 9. Includes (10X & 40X) lenses for measurement suitable to test wide .

does autoclaving kill fungal spores

The following issues may require instructions guidance provided by the manufacturer: how to operate the autoclave, the door safety mechanism, the dangers involved in circumventing safety means, how to ensure that the door .

knoop and vickers hardness test|knoop hardness test pdf